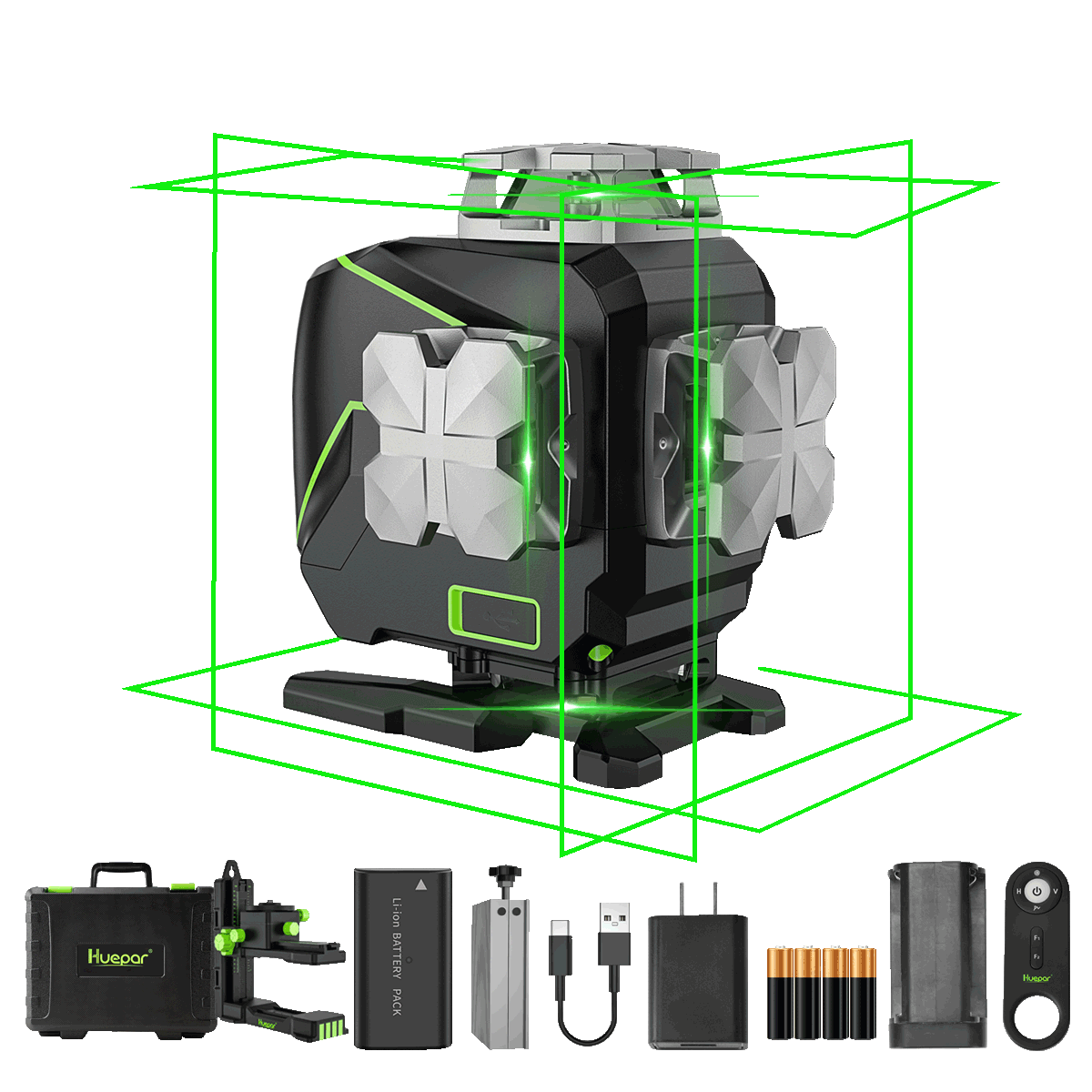

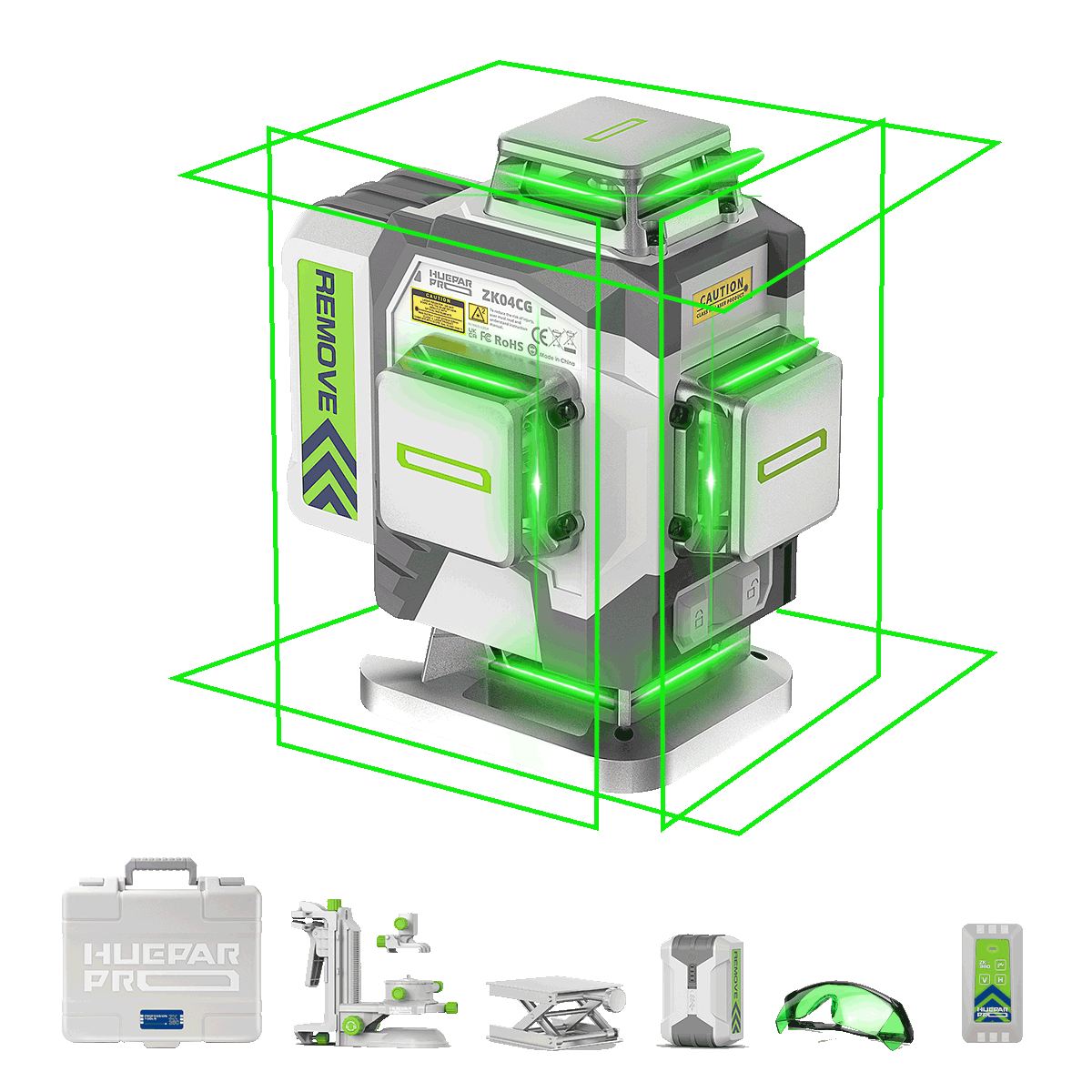

Upgrade Your Construction Toolkit: Hot Deals on 3D Laser Levels!

Understanding 3D Laser Levels and Their Uses

What Are 3D Laser Levels?

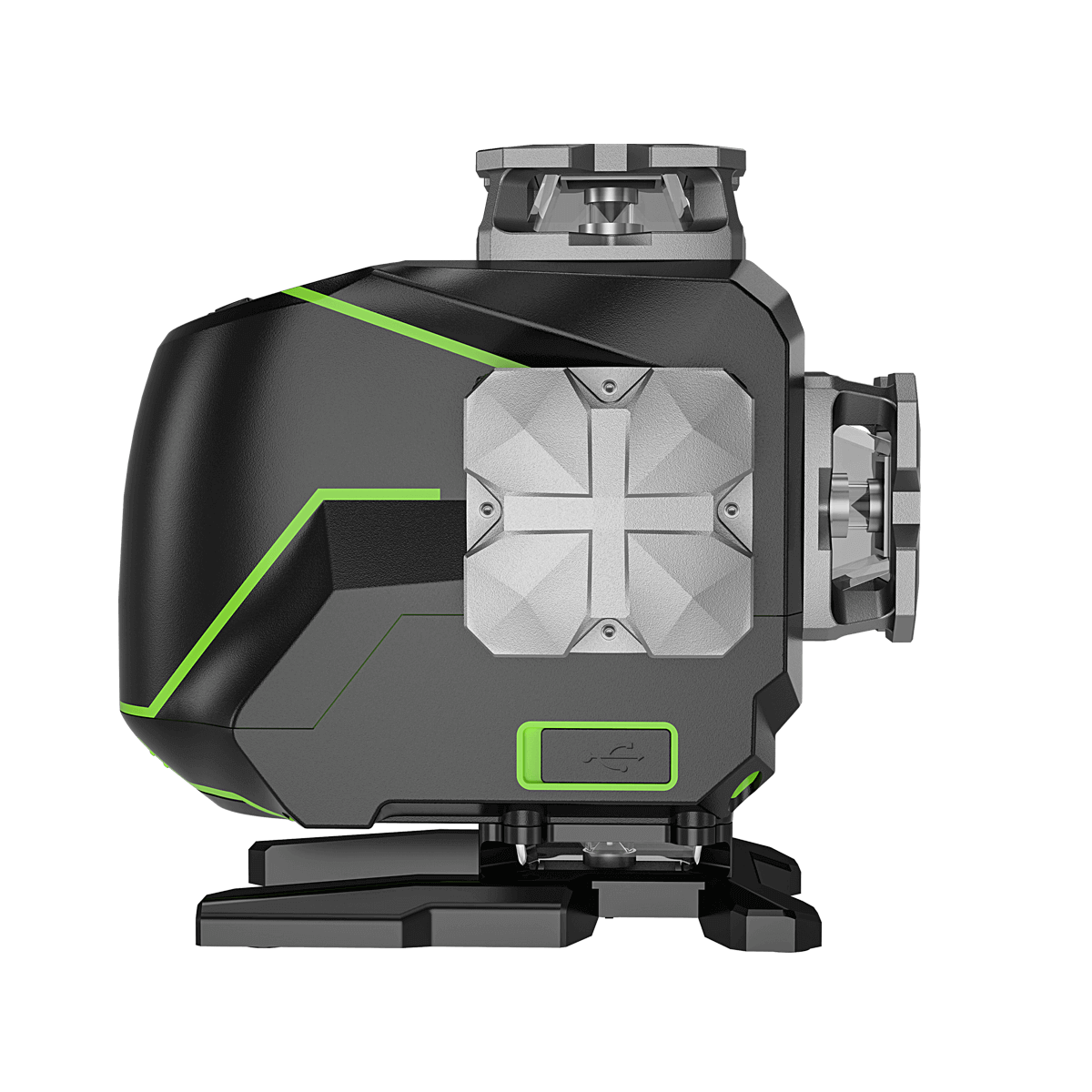

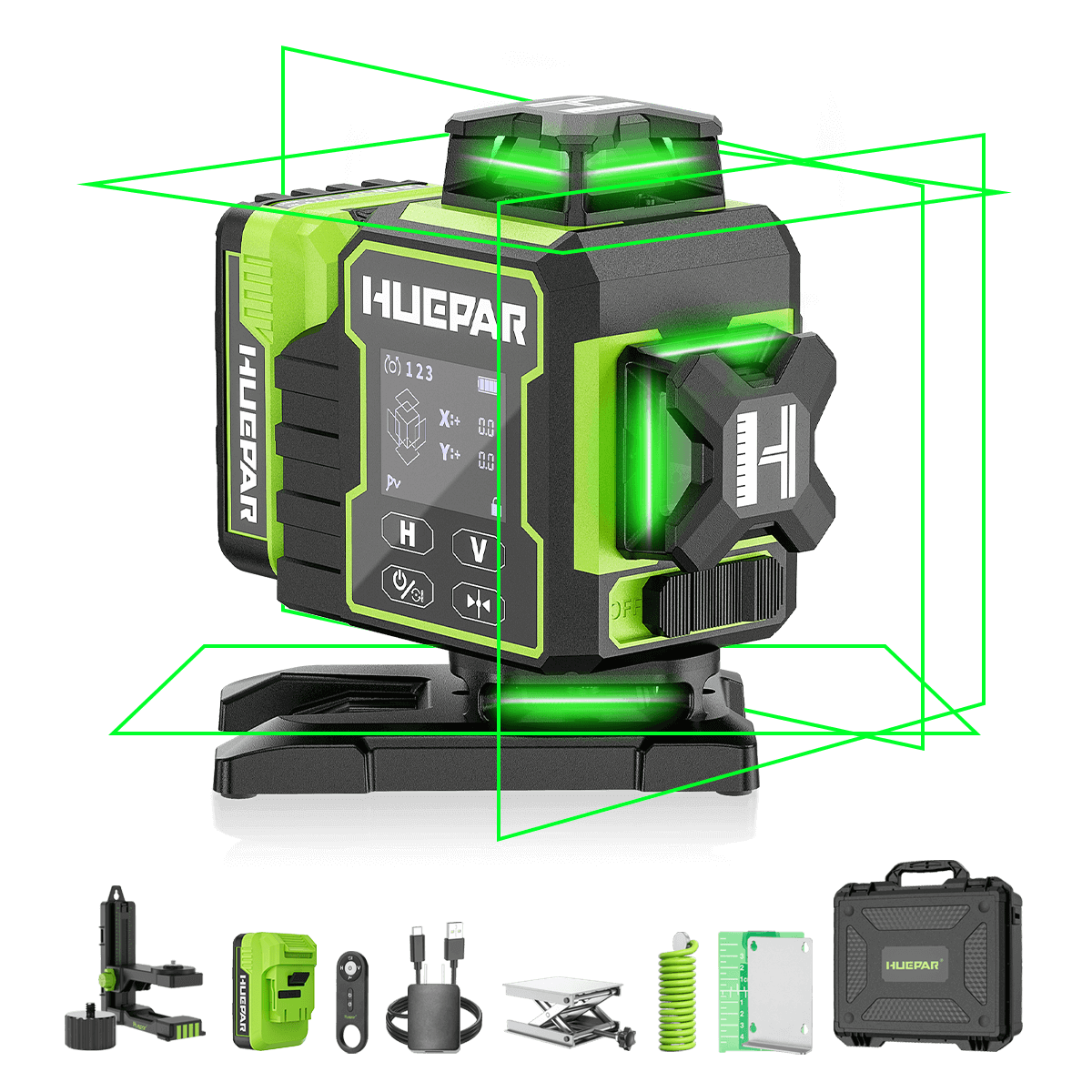

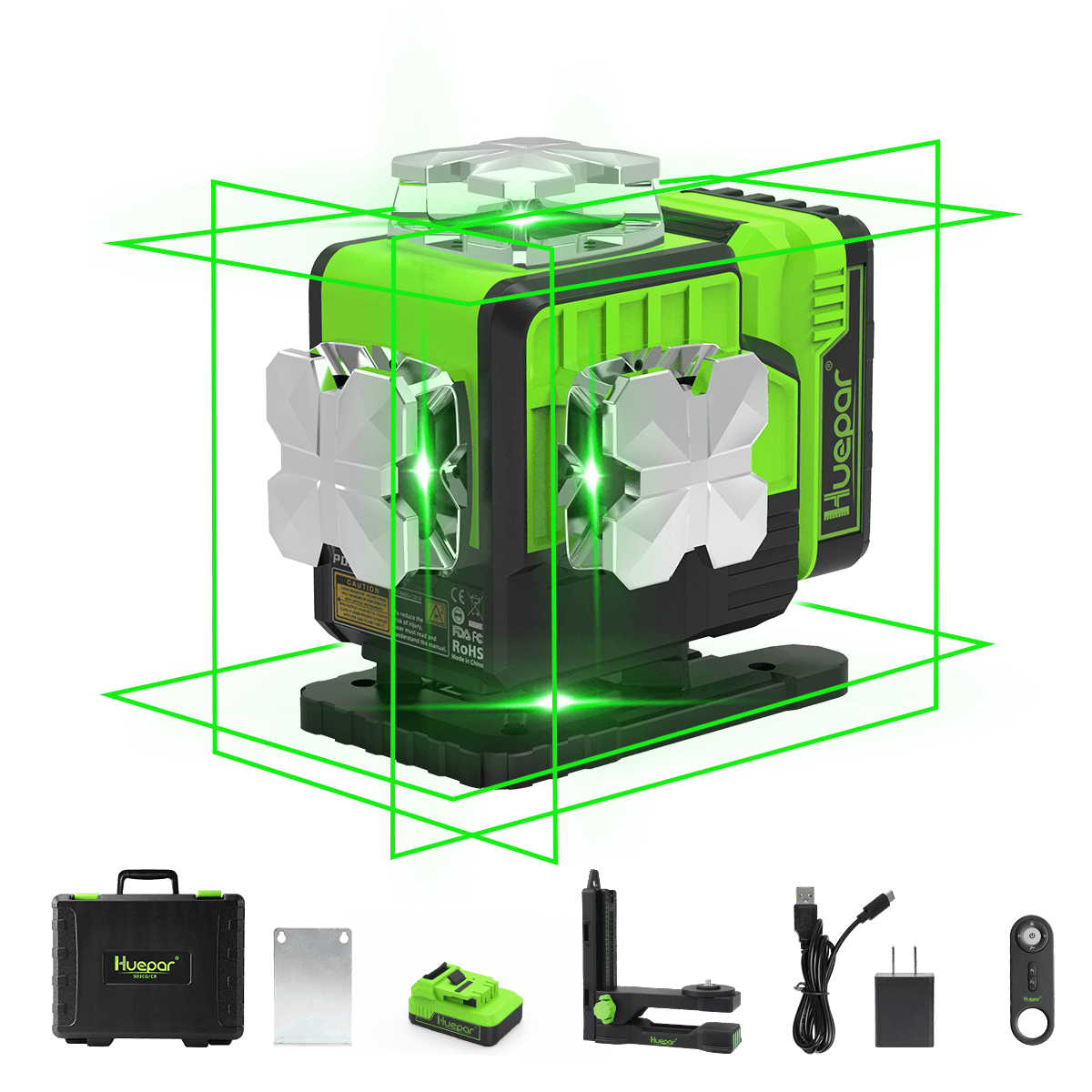

3d laser levels are tools for precise alignment. They project laser lines onto surfaces. These lasers show where to align or place items in construction projects. With advanced tech, they cast 360-degree lines. This means a full room layout from a single point. They are ideal for leveling floors, walls, and ceilings. They help to fit tiles, cabinets, or fixtures perfectly. These levels are a must for accuracy in building tasks.

Key Applications of 3D Laser Levels in Construction

3d laser levels are vital in various construction tasks. They aid in site layout and ensure precision. These levels are used for aligning walls and checking floor flatness. They also help install pipes, tiles, and fittings. Electricians use them to position outlets evenly. In large spaces, they ensure level ceiling and help with lighting setup. For landscapers, they assist in leveling ground and setting slopes. They are a must for builders wanting accuracy and speed.

The Benefits of Using 3D Laser Levels

3d laser levels offer many benefits in construction. They are precise and make alignment easy. You can use them indoors and outdoors. They save time on setting up lines for walls or tiles. These levels also reduce errors. This means less time fixing mistakes. The bright lasers are visible even in daylight, which is helpful. They can project a 360-degree plane for full room coverage. This feature is great for large projects. 3D laser levels are a smart choice for contractors.

Top Features to Look for in Cross Line Laser Levels

Accuracy and Precision: Why They Matter

When shopping for cross line laser levels, accuracy and precision are crucial. These features ensure you get the right measurements the first time. Look for units with high accuracy, typically within +/- 1/8 inch at 30 feet. A precise self-leveling feature can make your work faster and reduce errors. Levels with fine-tuning options allow for exact adjustments, which are vital in tasks like installing cabinets or laying tiles. Always check the specs for accuracy rates before buying to ensure precise and reliable readings.

Durability and Longevity: Investing Wisely

When picking a Cross Line Laser Level, durability is key. A durable level withstands tough sites and lasts longer. Look for these features:

- Rugged design to survive drops and impacts.

- Water and dust resistance, marked by IP rating, for all-weather use.

- Quality materials, like reinforced housing, protect internal components.

Investing in a sturdy laser level means fewer replacements and better return on your money. Make sure the one you choose can take on the rigors of daily use.

Ease of Use: Features That Save Time and Effort

Ease of use is crucial when selecting a cross line laser level. Look for user-friendly options that make setup quick and operations simple. Consider models with intuitive interfaces, clear instructions, and features such as self-leveling capabilities, which can drastically reduce time spent on adjustments. Quick access controls and the ability to save preferred settings can also enhance efficiency on the job site. Additionally, models that adapt easily to different working conditions with features like indoor/outdoor visibility modes are advantageous. When ease of use is prioritized, every task becomes faster and more accurate, leading to higher productivity and quality workmanship.

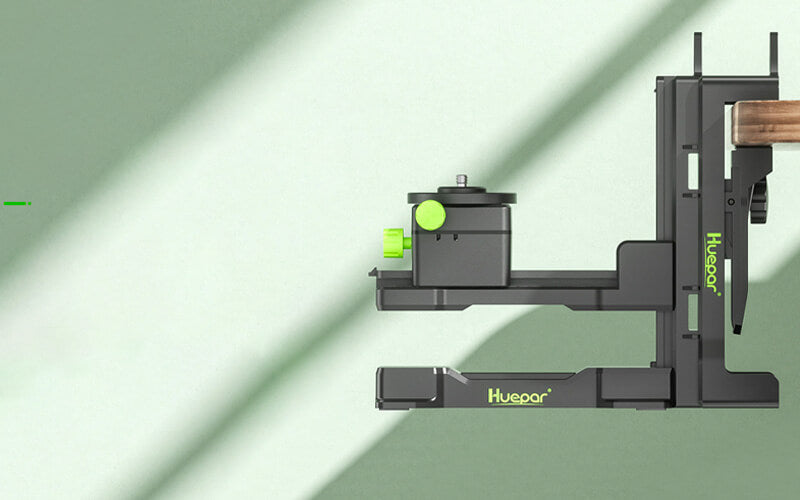

Finding the Right Tripod for Your Laser Level

Importance of a Stable Base

A stable base is crucial for laser level precision. It ensures the device stays fixed during measurements. An unsteady base can lead to errors, affecting project quality. A good tripod resists vibrations and movement. This stability is vital for both indoor and outdoor tasks. For accurate results, always start with a solid tripod foundation.

Tripod Compatibility with Various Laser Levels

When hunting for the perfect tripod to pair with your laser level, compatibility is key. Not all tripods are the same, and some are designed with specific laser levels in mind. Here's a quick overview to help you match your laser level with a suitable tripod:

- Check the Mounting Thread: Most laser levels require a 1/4-inch or 5/8-inch mounting thread. Ensure the tripod supports your laser level's threading.

- Consider the Head Type: Tripods come with flat or dome heads. Your laser level may need a particular type for optimal function.

- Review the Tripod's Weight Capacity: Your laser level's weight should be within the tripod's bearing limit. Overloading can cause instability.

- Brand-Specific Options: Some brands design tripods tailored for their laser levels. Check if such exclusive compatibility offers added advantages.

By ensuring compatibility, your tripod will support and enhance your laser level's performance reliably and safely.

Factors to Consider When Choosing a Tripod for Laser Levels

- Height Adjustability: Choose a tripod that offers a wide range of height options.

- Material Construction: Consider tripods made from aluminum or carbon fiber for lightweight durability.

- Head Type: Ensure the tripod head is compatible with your laser level, whether flat or domed.

- Leg Lock Type: Decide between flip locks and twist locks based on your preference for speed and stability.

- Stability and Footing: Look for tripods with sturdy feet. Check if they have spikes for outdoor use.

- Portability: If you move often, find a tripod that is easy to carry. Some come with shoulder straps.

- Load Capacity: Make sure the tripod can support the weight of your laser level and any extras.

- Price: Balance your budget with the features and durability you require from a tripod.